HPC User Report from A. Rausch (Chair of Materials Science and Engineering for Metals)

Influence of the Powder in Additive Manufacturing

The goal of our study is to examine the influence of the powder on a process window for powder fusion based additive manufacturing. The results show, for example, that higher powder bulk densities minimize the probability for binding faults and facilitate the usage of lower beam powers.

Motivation and problem definition

The porosity of parts is a crucial factor for parts that undergo mechanical loading. Especially, powder bed fusion based additive manufacturing techniques as Selective Laser Melting or Selective Electron Beam Melting suffer from residual porosity of built parts. Therefore, process windows can be determined that define the parameter ranges for dense parts. However, effects of the powder on such process windows are harder to quantify experimentally than for example the influence of the beam power. Here, numerical simulations can help to understand the underlying effects of different powder features. A major issue of simulating a whole process window for different additional parameters (as the powder bulk density) is the amount of numerical experiments that are required. A serial computation on one machine is not feasible because of the long simulation times. One simulation can last up to several days. Therefore, parallel computing of different parameters sets is inevitable to obtain results in an appropriate amount of time.

Methods and codes

The simulations are conducted with the OpenMP parallelized in-house software SAMPLE 2D written in C++. It is based on the Lattice Boltzmann Method and includes powder deposition, beam irradiation, heat transfer, melting, melt pool dynamics and resolidification.

Results

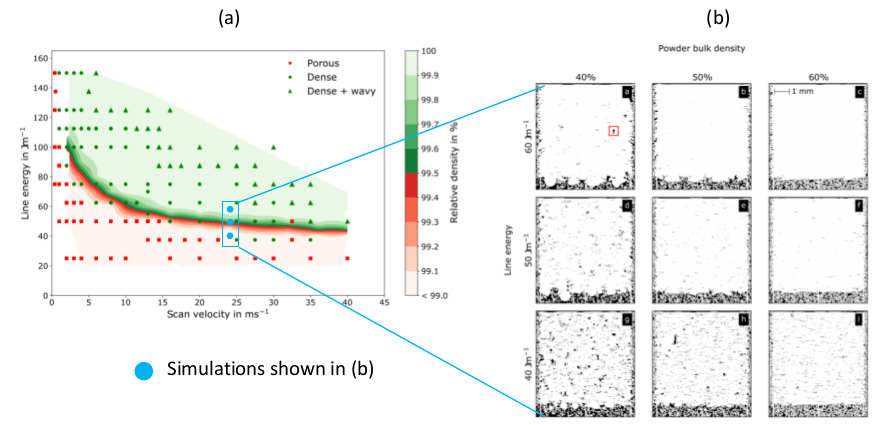

The results shown in the figure indicate that higher powder bulk densities are advantages to obtain dense parts at lower beam powers.

Process window for Ti-6Al-4V manufactured with SEBM showing the experimental results

(symbols) and the numerical results for the relative density (colormap) (a). Samples with a relative density higher than 99.5% are considered as dense. Additionally the influence of different energy inputs (line energies) are shown for different powder bulk densities (b-a – b-i). The parameters used therein are marked in (a) with blue dots. The figures are taken from [1].

Outreach

- Rausch, A.M.; Küng, V.E.; Pobel, C.; Markl, M.; Körner, C. Predictive Simulation of Process Windows for Powder Bed Fusion Additive Manufacturing: Influence of the Powder Bulk Density. Materials 2017, 10, 1117. 10.3390/ma10101117

A second paper for this topic is in progress.

Researcher’s Bio and Affiliation

Alexander Rausch received his bachelor’s and master’s degree in materials science and engineering at the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) in 2016. In the same year he started as a PhD student at the Chair of Materials Science and Engineering for Metals (FAU) under the supervision of Dr.-Ing. Matthias Markl and Prof. Dr.-Ing. habil. Carolin Körner.