HPC User Report from M. Münsch (Chair of Fluid Mechanics)

Improved Thermoforming Process using the Forming-Air Impact Technology

Using the thermal and dynamic effect of air jets directed through the forming air inlet nozzles during the thermoforming process, an optimized deformation behavior can be observed, ultimately leading to decreased consumption of raw material and thus a reduction of plastic waste.

Motivation and problem definition

For simply shaped thin-walled plastic mass products, thermoforming is a standard manufacturing method. A main drawback of the common process is an inhomogeneous wall thickness distribution, causing excess raw material consumption. One way to alleviate this problem is to impose an optimized temperature distribution in the raw material, which leads to a favourable deformation behavior. The approach followed within this project to influence the plastic sheet temperature during the process is by using air jets. What makes this project unsuitable for a purely experimental investigation is the large number of potentially influential parameters. The conduction of extensive parameter studies therefore has to be done numerically. In order to simulate this complex thermal fluid-structure interaction (TFSI) problem, an implicitly coupled TFSI model of the thermoforming process is being set up. Furthermore, various reduced-physics models are investigated.

The aim is to gain an in-depth understanding of the thermoforming process so that an optimization towards a reduction of the material consumption can be performed. Experimental parameter studies are used for validation and back-up of the model.

Methods and codes

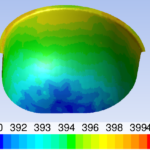

[K] on the plastic sheet lose to the end of the deformation process

Results

The positive effects and feasibility of the technology could be confirmed. Ongoing work seeks to exactly reconstruct the chain of effects between the large number of physical effects involved in the process and to identify the best parameters for improvement from an industry-oriented point of view.

Outreach

- Nine oral presentations at conferences and fairs

- Four written publications

The IGF projects 18536 BG and 20587 BG/2 of the Industry Association for Food Technology and Packaging (IVLV) was funded via AiF within the programme for promoting the Collective Industrial Research (IGF) by the German Federal Ministry for Economic Affairs and Energy (BMWi) on the basis of a resolution of the German Parliament.

Researcher’s Bio and Affiliation

Research on this topic is conducted within the research group ‘Numerical Fluid Mechanics’ at the Institute of Fluid Mechanics at FAU (Dr.-Ing M. Münsch and others) in cooperation with Fraunhofer IVV, Branch Lab for Processing Machinery and Packaging Technology Dresden (Dipl.-Ing. F. Kayatz and others).