HPC User Report from L. Eckendörfer (Catalytic Reactors and Process Technology)

Investigation of fluid flow, mass transfer and chemical reactions in complex catalyst support structures

CFD simulations coupled with detailed kinetic reaction mechanisms are applied within in operando adjustable complex catalyst support structures to gain a detailed understanding of the geometrical influence on catalytic processes.

Motivation and problem definition

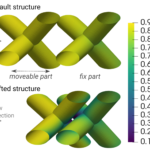

Additive manufacturing offers an enormous flexibility for the design of catalyst support structures for heterogeneously catalysed reactions. Interpenetrating periodic open cellular structures (interPOCS) are a special type of such structures. The basic building block of these periodic structures is a diamond unit cell which is repeated in every spatial direction, and therefore forms a continuous solid network. In interPOCS, two of these networks are interwoven and can be shifted against each other in operando. In this way, the flow field, mass transfer and chemical reactions within the structure can be affected.

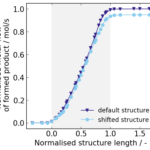

In order to investigate the influence of the complex geometry itself and the offset (characteristic value for the shift of the two interwoven solid networks relative to each other), CFD is the most appropriate tool. Thus, different simulations for a certain structure were carried out in order to improve the understanding of how the structure and its offset affect the flow, and thereby important characteristics for chemical reactor design, such as residence time, tortuosity and conversion

Methods and codes

Simulations are carried out within the framework of the open source CFD software OpenFOAM. For investigations regarding the mass transfer analysis, the in-house developed solver toolkit disTrackFoam which is based on the principle of Lagrangian particle tracking is used. For the transient simulation of heterogeneously catalysed reactions, the solver CatalyticFOAM (Maestri, M.; Cuoci, A. (2013)) is applied.

Results

The velocity and pressure field in the structure was determined for different superficial velocities under laminar and turbulent flow conditions and for different offset positions. The flow field in combination with particle tracking was used to determine residence time distribution, hydrodynamic dispersion and tortuosity. The results demonstrate that all of these quantities can be influenced by shifting the structure. This change of the flow influences as well a chemical reaction taking place in the structure. Simulations of heterogeneously catalysed gas phase reactions verified that the conversion varies due to the change of the surface utilisation caused by the shielding of some parts of the structure. Findings can now be used to further adjust and optimize the geometry of the interPOCS according to specific requirements.

form A + B -> C.

Outreach

- Trunk, S.; Do, G.; Schwieger, W.; Freund, H.: Numerical Investigations of Adjustable Mass Transport

Characteristics in Interpenetrating Periodic Open Cellular Structures (interPOCS), 6th International

Conference on Structured Catalysts and Reactors, Bad Herrenalb, Germany, September 2019. - Trunk, S.; Do, G.; Schwieger, W.; Freund, H.: Catalyst Support Structures with in operando Tunable

Transport Properties Enabled by Additive Manufacturing, 1st International Conference on

Unconventional Catalysis, Reactors and Applications, Zaragoza, Spain, October 2019. - Trunk, S.; Do, G.; Schwieger, W.; Freund, H.: Additive Manufacturing of Catalyst Support Structures

with in operando Adjustable Mass Transport and Flow Characteristics, AIChE Annual Meeting,

Orlando, FL, USA, November 2019.

Researcher’s Bio and Affiliation

This topic is part of the research in the group “Catalytic Reactors and Process Technology” by Prof. Dr. H. Freund at the Institute of Chemical Reaction Engineering. Lisa Eckendörfer is mainly focusing on the simulation of chemical reactions and Andreas Brix on particle tracking. Both studied Chemical and Biological Engineering and are Ph.D. students in the group since 2019.